Mhedzisiro ye Drill neNickel pane iyo Thermal Kukuvadza Kuramba kwe4Cr5Mo2V Kufa Kukanda Kufa Simbi

4Cr5 Mo2V ndiyo inowanzoshandiswa kufa-kukanda kufa simbi. Mukuita kwekufa-kukanda aruminiyamu chiwanikwa, nekuda kwekuderera uye kunamatira kwealuminium yakanyungudutswa, iyo fomu inotambura kukuvara kwemafuta, senge kuneta kwemafuta uye kupisa kwemafuta kunonyungudika, zvichikonzera kuderera mukuomarara kwayo uye kunyange kukurumidza kukundikana.

Kuti uwane kudzidza kana nickel kana kuoma kunogona kuvandudza kupisa kwemafuta kukanganiswa kwealuminium alloy die-casting molds, 4Cr5 Mo2V simbi uye 4Cr5Mo2V simbi yekuyedza mabhuroko ane 1% Ni uye 1% Co (mashoma chidimbu) akagadzirwa, uye iwo akavezwa mushure kudzima uye kutsamwa. Mune yakagadziriswa kufa yefa-yekukanda muforoma, iyo ADC12 aruminiyamu chiwanikwa chine tembiricha ye800 ℃ yakazofa ikafa-kukandwa mazana maviri kusvika chiuru nguva, uye macro morphology uye kuomarara kwepamusoro kwebvunzo block kwakaongororwa.

Mhedzisiro yacho inoratidza kuti mushure mekufa-kukanda aruminiyamu chiwanikwa chiuru nguva, iyo 1,000Cr4Mo5V simbi bvunzo block yakanamatira kune aluminium zvakanyanya zvakanyanya uye yakaburitsa mashoma mashoma mambure-kunge kutsemuka; iyo Ni-iine simbi yekuyedza block yakanamatira kune aluminium, uye iyo Co-iine simbi bvunzo block yakanamatira kune aruminiyamu zvishoma, zvichiratidza kuti izvo zviri mukati me2% Co 1Cr4Mo5V simbi ine yakanakisa yekupisa yekukuvara kuramba kuti kufa-kukanda aruminiyamu alloys. Uye zvakare, tichienzanisa neukukutu usati wafa-uchikanda aruminiyamu chiwanikwa, mushure chiuru nguva kufa-kukanda, kumeso kuomarara kwe2Cr1,000Mo4V simbi, nickel-ine uye yakaoma-ine 5Cr2Mo4V simbi mienzaniso yakaderera ne5, 2 uye 2.8 HRC, ndokuti, akawanda kufa-achikanda aruminiyamu alloys. Iyo yakashata mhedzisiro yekuoma kwepasi kweiyo nickel-ine uye yakaoma 1.8Cr1.4Mo4V simbi iri shoma pane iyo ye5Cr2Mo4V simbi, inoenderana neyakaomesesa mhinduro yekusimbisa mhedzisiro yeCo neNi, iyo inobatsira kuvandudza aruminiyamu emvura kukukurwa kusagadzikana kweiyo chakuvhuvhu ichi uye chinoita kuti chakuvhuvhu chisatapukirwe nemafuta.

Aluminium chiwanikwa kufa-kukanda kwakaomarara kwepamusoro-tembiricha uye yakanyanya-kumanikidza maitiro. Pane zvinhu zvakawanda zvinokanganisa kupisa kwemafuta (kusanganisira kupisa kwekushisa uye kurasikirwa kwemafuta) kuita kwealuminium alloy die-casting molds. Pakati pavo, kuumbwa kweinopisa-basa kufa simbi inonyanya kukosha.

Under kwomuzvarirwo ezvinhu, kukundikana kufa vachikanda vanofa nekuda kutsemuka uye epurasitiki deformation inogona kudzivirirwa. Kutsemuka kweforoma kunowanzo kukonzerwa netsaona yekuwandisa kana kupisa kwemhepo, zvichikonzera kushushikana kwakanyanya. Pakutanga kupisa kwekuneta kutsemuka uye kurasikirwa kwekutema (pamusoro pekupisa tembiricha) yekufa-kukanda mafuru ndiwo makuru ekundikana modes, uye iwo maviri anowanzo kukanganisa mumwe nemumwe. 4Cr5Mo2V simbi iri inoshandiswa zvakanyanya kupisa basa kufa simbi, ine yakanaka yekupfeka kuramba uye epurasitiki deformation kuramba. Drill uye nickel zvinowanzo shandiswa kuisa zvinhu muchiyero, izvo zvinogona kunyatso kuwedzera simba uye kuomarara kwesimbi, uye kuve neimwe mhedzisiro pakuramba kupisa kwemafuta. Naizvozvo, 4Cr5Mo2V simbi, 4Cr5Mo2V ine 1% Ni uye 1% Co (mashoma chikamu, zvakafanana pazasi) zvinodzidziswa. Kuramba kwesimbi kune yakaumbwa nesimbi yakanyungudutswa kwakakosha zvikuru kutungamira kugadzirwa chaiko.

Nekudaro, nzira zhinji dzekudzidza kupisa kwekufa kwe-kufa-kukanda kufa simbi pamberi pemuromo kuenzanisa kupisa uye kutonhora. Iyo die simbi sampuro haibatanidze zvakananga iyo yakanyungudutswa aluminium, uye haibatanidze iyo yekuzvambura mhedzisiro yeiyo yakanyungudutswa aluminium, senge yakananga induction kudziya kweiyo kufa simbi sampuli. -A. Mune bepa iri, matatu-echinhu muforoma simbi bvunzo mabhuroko akagadzirwa uye akaisirwa mukati kufa-kukanda chakuvhuvhu kuita kufa-Kudzingwa bvunzo yeADC12 aruminiyamu chiwanikwa. Kukuvadza kuita kwealuminium yakanyungudutswa.

1.Test Zvishandiso Uye Maitiro

1.1 Zvekuedzwa Zvishandiso

Iyo makemikari akaumbwa e4Cr5Mo2V simbi, 4Cr5Mo2V simbi ine 1% Ni (inozotevera kunzi 4Cr5Mo2V + Ni simbi) uye 4Cr5 Mo2V simbi ine 1% Co (pano inonzi 4Cr5Mo2V + Co simbi) inoratidzwa muTafura 1. Muedzo wacho waive yakakandwa neADC12 Iyo makemikari akaumbwa ealuminium alloy inoratidzwa mu Tafura 2.

| Tafura 1 Makemikari akaumbwa eakaferefetwa kufa-achikanda kufa simbi (mashoma chidimbu)% | |||||||

| zvinhu | C | Cr | Mo | V | Co | Ni | Si |

| 4Cr5Mo2V simbi | 0.39 | 4.65 | 2. 21 | 0.46 | - | - | 0. 23 |

| 4Cr5Mo2V + Ni simbi | 0.38 | 4.72 | 2.34 | 0. 51 | - | 1.02 | 0. 21 |

| 4Cr5Mo2V + Co simbi | 0.41 | 4.67 | 2.40 | 0.48 | 1.03 | - | 0. 24 |

| Tafura 2 Chemical Kuumbwa Kweiyo ADC12 Aluminium Alloy% | |||||||||

| eremendi | Cu | Mg | Mn | Fe | Si | Zn | Ti | Pb | Sn |

| Quality Score | 1.74 | 0.22 | 0.16 | 0.76 | 10.70 | 0.87 | 0.064 | 0.035 | 0. 010 |

1.2 Bvunzo Nzira

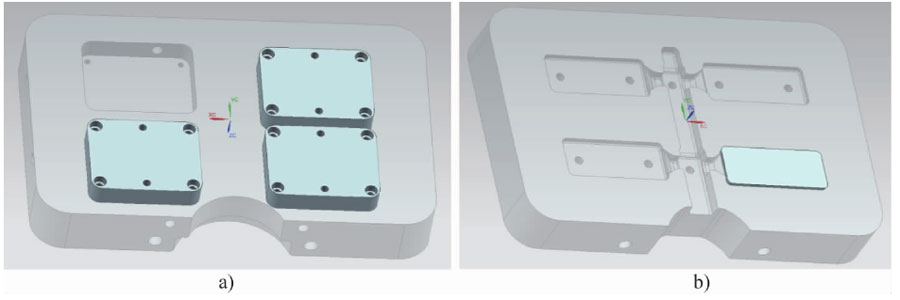

Iyo yakakwenenzverwa 4Cr5Mo2V simbi, 4Cr5Mo2V + Ni simbi uye 4Cr5Mo2V + Co simbi yakagadziridzwa kuita mabhureki ekuyedza sezvakaratidzwa muMufananidzo 1. Mushure mekupedza vhoriyamu, vakatsamwiswa kaviri, nekuoma kweinosvika 47 HRC, uye ivhu rakatsetseka kubvisa chiyero che oxide.

Boka nhamba rebvunzo bvunzo rakaiswa mukati mevhu yeiyo yakagadziriswa muforoma, uye iyo mhango yefa-yakakanda aruminiyamu chiwanikwa chakaiswa mune chinofambika muforoma, sezvakaratidzwa mumufananidzo 2. A 500 t yakatwasuka kamuri inotonhorera kufa-yekurasa muchina uye choga chakazvigadzirira chakashandiswa pakuedza kwekufa kweADC12 aluminium alloy sheet, uye iyo aluminium alloy yakashandiswa zvekare. Iyo tembiricha yealuminium yakanyungudutswa iri pamusoro, 800 ° C, kuitira kuti ikwirise bvunzo (kazhinji, iyo yekufa yekukanda tembiricha yeADC12 aluminium alloy iri (650 120) ° C). Sezvo tembiricha yesimbi yakanyungudutswa iri 800 ℃, iyo isingasvike panonyungudika iyo Fe-A1 intermetallic komputa, iyo inoguma inovhengana ichave iripo mune yakanyungudutswa aluminium semarara mushure mekudonha. Iko kudzokororwa kwekushandisa kwesimbi yakanyungudutswa kunokonzeresawo kuwedzera kwetsvina nekusimbisa iyo aluminium. Kuzvuka kwemvura, nokudaro kuchimhanyisa bvunzo.

Mushure mekuedzwa kwekufa, stereo microscope yakashandiswa kutarisa iyo aluminium adhesion phenomenon pamusoro penzvimbo yekuyedza; Ultra-yakadzika-ye-munda maikorosikopu yakashandiswa kuenderera mberi nekuona mwero wealuminiumhesisi yekunamatira uye kana paive nekutsemuka pamusoro penzvimbo yekuyedza.

2.Test Mhedzisiro Uye Ongororo

2. 1 Surface Morphology Yeiyo Bvunzo Bvunzo

2.1.1 Pamusoro Pakanamatira Aluminium

Mufananidzo 3 inoratidza yekumusoro morphology yeaya matatu esimbi bvunzo matombo pasina kufa kukanda uye mushure mazana mazana matanhatu nezviuru enguva dzekufa kukanda. Inogona kuonekwa kubva kuMufananidzo 600,1000 (b, e, h) kuti mushure memazana mazana matanhatu ekufa-kukanda, iyo 3Cr600Mo4V simbi bvunzo block ine yakanyanya kukomba aruminiyamu kunamatira.

Iyo 4Cr5Mo2V + Co simbi bvunzo bhuroko inonamira kune mashoma aruminiyamu. Mufananidzo 3 (c, f, i) inoratidza kuti kunamatidzwa kwealuminium pamusoro pematombo matatu ebvunzo kwakawedzera mushure menguva chiuru dzekufa-kukanda. Iko pamusoro peiyo 1,000Cr4Mo5V yesimbi bvunzo block ine yakajeka aruminiyamu kunamatira, nepo mamwe maviri mabvunzo mabhureki ane mashoma aruminiyamu kunamatira. Iyo 2Cr4Mo5V + Co simbi bvunzo Iyo bundu realuminium ndiyo shoma uye yunifomu, zvichiratidza kuti iyo dhayamondi-ine 2Cr4Mo5V simbi ine yakanakira kuramba kukuvara kwemvura aluminium kukuvara, nepo iyo 2Cr4Mo5V simbi iri yakaipisisa. Iko kuwedzerwa kwekuboora uye nickel zvinhu zvinobatsira kudzikamisa iyo yakanyanya tembiricha kuomarara kwefa simbi 2-9, uye pamusoro hazvisi nyore "kunyorovesa" panguva yakadzokororwa kusangana ne yakanyungudutswa aluminium, saka emvura aruminiyamu kukwira kuramba kuri nani, uye aluminium adhesion zvishoma. Munguva yekufa-kukanda bvunzo, iyo yakanyungudutswa aluminium inopinda mudumbu kuti ibate bvunzo block, uye isina kuenzana chimiro chebvunzo block, nzvimbo yemuchina kuremara nzvimbo nedzimwe nzvimbo dzemuno dzinonamira zvishoma kune aluminium. Iyo aruminiyamu iri munzvimbo yealuminium-yakasungwa inoenderana nesimbi kuti igadzire Fe.} Al brittle yepakati mukomboni, iyo ichavhunika uye kusvuurwa pasi pekupwanywa kweiyo yepamusoro-yekumanikidza aluminium mvura, zvichikonzera makomba ari pamusoro peforoma pamusoro, uye nezvimwe chakakomba aruminiyamu kubatana pasi pekukweshwa kwealuminium mvura.

2.1.2 Surface Kutsemuka

Mufananidzo 4 unoratidza iyo yepamusoro-kudzika kwemunda morphology ye4Cr5Mo2V simbi, 4Cr5Mo2V + Ni simbi uye 4Cr5Mo2V + Co simbi mienzaniso mushure menguva chiuru chekufa kwekukanda. Inogona kuonwa kubva kuFiri. 1,000 (a) kuti kune diki diki yezvimedu-zvidimbu zvakagovaniswa mune ingangoita mambure chimiro pamusoro peiyo 4 Cry Mot V yesimbi bvunzo. Iyo inonamatira aruminiyamu uye yakanyungudutswa aluminium inoita nesimbi kuti igadzire Fe.} Al makomponi. Iyo coefficient yekupisa kwekuwedzera kweFe.} Al rakasiyana neiro rematrice, zvichikonzera mune diki diki kwazvo ma microcracks mune anonamatira aruminiyamu uye Fe.} Al nemakomponi. Kurohwa kwealuminium yakanyungudika kunokonzera kuti ma microcracks apararire, uye iyo aluminiyamu yakanyungudika inopinda mukati mekutsemuka uyezve inopindirana nematrix kuumba Fe 4 Al makomponi. Mukutevera kwakadzokororwa kufa-kwekukanda maitiro, iyo Fe.} Al macomputer ari pamusoro peyero block bvisa kuti aumbe makomba. Mushure mekunhonga uye kuchenesa kweiyo ultrasonic, pamusoro peiyo bvunzo block yakaonekwa yakafanana neteti-senge aruminiyamu mvura yekutsvaira hunhu. Mufananidzo 2 (b, c) unoratidza kuti hapana kutsemuka muiyo 4Cr4Mo5V + Co simbi uye 2Cr4Mo5V + Ni simbi bvunzo mabhuroko, zvichiratidza kuti kuwedzerwa kwe2% chibooreso kana molybdenum hakugone chete kudzora kubatisisa kwepamusoro kwealuminium, asiwo kuderedza kutsemuka kweforoma uye nekuvandudza aruminiyamu kuramba Liquid kukuvara kuita. Kuwedzerwa nickel nedhaimani isiri-carbide inoumba zvinhu inogona kuvandudza yakanyanya-tembiricha kuomarara kweforoma, uye dhaimani inogona zvakare kukurudzira kupararira uye kunaya kwemolybdenum carbide panguva yekupisa, uye nekuwedzera kunaya kuomesa mhedzisiro 'z-} 1. Tsvagurudzo yaLing Qian et al. yakaratidza kuti kuwedzerwa kwezvinhu zvinodzikamisa austenite kufa-kukanda kufa simbi kunogona kudzikisira kushushikana. Ose ekuboora uye nickel zvinhu zvinowedzera nzvimbo yeaustenite, saka 3Cr4Mo5V + Ni simbi uye 2Cr4Mo5V + Co simbi inofa ichikanda mafichi nzvimbo haigone kutsemuka.

Iyo yakanyungudutswa aluminium mune chaiyo kufa-yekukanda maitiro yakasimba kwazvo kurwisa chakuvhuvhu. Zvinoenderana neiyo Fe-A1 chikamu dhizaini, iyo Fe-Al inopindirana makemikari akaumbwa nekuita kwesimbi uye yakanyungudutswa aluminium anowanzo kuve FeAlz, Fez A15, FeA13, nezvimwewo, izvo zvinopwanya. Chikamu cheAl-rich chealuminium alloy chichaita. bvarura matrix uye upinde iyo yakanyungudutswa aluminium pasi pekupwanywa kweiyo yakanyungudutswa aluminium, ichisiya makomba ari pamusoro peiyo furu. Iko kusanganiswa kwechikamu chealuminium alloy uye iyo makomba eforoma ine simba uye haidonhe, uyezve inoumba mafomu eA A1. Iyo aluminium, Fe.} Al uye makomputa anonamatira ipapo anotarisana nema microcracks panguva yekutonhora. Yekufa-yekukanda jira ine shoma emvura aruminiyamu, saka inosimbisa nekukurumidza, uye kuita pakati peforoma nemvura aruminiyamu inononoka. Naizvozvo, pamusoro peiyo bvunzo block ine mashoma makomba nekuda kwekuita kwaFe uye Al, uye yakawanda inonamira aluminium inogadzirwa nekukukurwa kwealuminium mvura.

2. 2 Kuomarara kwepamusoro

Tafura 3 ndiyo avhareji kukosha kwepamusoro kuomarara kweatatu kufa simbi bvunzo mabhureki mushure menguva dzakasiyana dzekufa kukanda. Iyo data iri muTafura 3 inoratidza kuti kuomarara kwepasi kwemhando nhatu dzekuyedza kunodzivirira zvese zvishoma. Sezvo huwandu hwekufa kwekukanda mafuru hunowedzera, zvakaenzana nekudzokorodza kutsamwa kweiyo bvunzo block, saka kuomarara kunoderera. Mushure menguva chiuru dzekufa-kukanda, kuomarara kweiyo 1,000Cr4Mo5V + Co simbi bvunzo block ine kuderera kudiki, inova 2 HRC; iyo 1.4Cr4Mo5V simbi yekuyedza block ine kuderera kuri pachena.

Zviripachena, yakadonha ne 2. 8 HRC; kuoma kwepamusoro kweiyo 4Cr5Mo2V + Ni simbi bvunzo block yakadonha ne1 HRC. Kugadzikana kweforoma kuomarara kunobatsira kudzora aruminiyamu kunamatira, ndiko kuti, zvinobatsira kuramba kufa-kukanda kupisa kwemafuta.

| Tafura 3 Surface kuomarara kwemuedzo wekuvhara mushure mekufa kwekukanda kwenguva dzakasiyana% | ||||||

| zvinhu | Kwete Kufa Kanda | 200 Times | 400 Times | 600 Times | 800 Times | 1000 Times |

| 4Cr5Mo2V simbi | 48.6 | 48.4 | 48.1 | 47.2 | 46.9 | 45.8 |

| 4Cr5Mo2V + Ni simbi | 47.5 | 47.4 | 47.2 | 46.8 | 46.9 | 46.1 |

| 4Cr5Mo2V + Co simbi | 47.7 | 47.5 | 47.1 | 46.5 | 46.2 | 45.9 |

Mushure menguva refu yekupisa kwesimbi yekufa, iyo martensite inoora uye yechipiri carbides inova yakaoma, zvichikonzera kuderera kwekuoma kwepamusoro. Ose mabhora uye nickel zvinhu zvisiri-carbide zvinoumba zvinhu, izvo zvinogona kutsiva Fe maatomu kuita kuti simbi yakasimba mhinduro isimbise '5 kusvika' 8, kuitira kuti chakuvhuvhu chiwedzere chakakwirira tembiricha simba uye inochengetedza yakakwirira kuomarara mushure mekudzokorora nekukurumidza kupisa uye kutonhora. China China Inokanda Association yakadzidza kugoverwa kwechinhu mune yakadzimwa uye yakatsamwa simbi yeCr-Mo-V-Ni, ndokuona kuti panguva yekutsamwa, zvinhu zveNi zvichawedzerwa zvakapoteredza carbides, zvichidaro zvichitadzisa maatomu ekabhoni mune ferrite yakatenderedza iyo carbides Iyo inoramba ichipararira yemakarubhu inowedzera simba rekumisikidza carbide inoomesa, inotadzisa kukura kwe carbides, nokudaro ichideredza kuomarara kudonha kweinickel-ine 4Cr5Mo2V simbi, uye nekuvandudza kupokana kwayo nekunyungudutswa kwealuminium kukuvara.

The China Die Kukanda Association akadzidza kudziya kugadzikana uye microstructure shanduko kufa simbi pamwe 1% Ni uye pasina Ni, uye vakaona kuti mune yekupedzisira nhanho yekupisa kugadzikana bvunzo, nickel inononoka kudzika kwekuoma kwesimbi inofa, nekudaro kugadzira iyo simbi iri nani panyama inodzora pabonde. Kuchera chinhu chinowedzera iyo austenite phase zone. Kuwedzera chibooreso kuna 4Cr5Mo2V simbi inogona kusimudzira kuparara kwe carbides panguva yekumisa austenitization maitiro, kuwedzera kabhoni zvemukati meaustenite, uye kuwedzera kugadzikana kweaustenite, nokudaro ichiwedzera iyo yakachengetwa austenite Iyo huwandu hweensensite uye kuomarara kwemartensite, uye chibooreso chinogona zvakare kusimudzira kupararira uye kunaya kwemolybdenum carbide panguva yekutsamwa, uye kusimudzira kunaya kuomesa mhedzisiro z'-1.

Iyo yekusimbisa mhedzisiro yenickel uye chibooreso pane iyo matrix inoita iyo kufa simbi bvunzo block ichiri iine yepamusoro pevhu kuomarara mushure mekudzokorora kurohwa kweiyo yakanyungudutswa aluminium, kuitira kuti ive inopokana nekukukurwa, izvo zvinobatsira kugadzirisa kusagadzikana kweye bvunzo block kune kukuvadzwa kwealuminium yakanyungudutswa. Iko kuomarara kwepamusoro kweiyo bvunzo block uye iyo degree yealuminiumisi yekunamatira inoratidza zvakare (ona Mufananidzo 3, Tafura 3): Iyo yakaboorwa 4Cr5 Mo2V simbi bvunzo block ine mashoma emvura makomba uye aruminiyamu kunamatira mushure menguva chiuru chekufa-kukanda, ndokuti, kuramba aruminiyamu mvura kukuvara ndiyo yakanakisa. Naizvozvo, iko kusimbisa kwekuwedzera kwe1,000% Co kune simbi kwakakura kupfuura kuwedzera 1% Ni, ese ari maviri anobatsira kugadzirisa iyo anti-aluminium kukuvara kuita kwefa simbi.

3.Conclusion

- Mushure mekufa-kukanda aruminiyamu chiwanikwa ka1 nguva, iyo 000Cr4 Mo5V simbi simbi ine chibooreso inonamira iyo isingasviki aluminium, uye iyo 2Cr4Mo5V simbi sampuro inonamira iyo yakawanda aruminiyamu, ndokuti, iyo 2Cr4 Mo5V simbi ine drill ine yakanakisa yekupisa yekukuvara kuramba.

- Mushure mekufa-kukanda aruminiyamu chiwanikwa kakapetwa ka1,000, kuoma kwepamusoro kwe4Cr5Mo2V simbi, 4Cr5Mo2V + Ni simbi uye 4Cr5Mo2V + Co zviumbwa zvesimbi zvakaderera ne2.8, 1.8 uye 1.4 HRC, ndiko kuti, kuwedzerwa nickel kana chibooreso kunogona kuwedzera zvakanyanya Thermal kukuvara kuramba pamusoro 4Cr5Mo2V kufa-vachikanda vanofa simbi.

Ndokumbirawo uchengete kwainobva nekero yechinyorwa chino kuti iprote zvakare: Mhedzisiro ye Drill neNickel pane iyo Thermal Kukuvadza Kuramba kwe4Cr5Mo2V Kufa Kukanda Kufa Simbi

Minghe Kambani Inokanda Kambani dzakatsaurirwa kugadzira uye kupa mhando uye epamusoro kuita Kukanda Zvikamu (simbi kufa zvikamu zvekukanda mhando zvinonyanya kusanganisira Mutete-Wall Yakakanda Kukanda,Hot Chamber Die Kukanda,Cold Chamber Die Kukanda), Round Sevhisi (Die Kukanda Service,Cnc machine,Kugadzira Mould, Surface Kurapa) .Chero tsika yeAluminium kufa kukanda, magnesium kana Zamak / zinc kufa kukanda uye zvimwe zvinodiwa zvekukanda zvinogamuchirwa kuti utibate.

Pasi pekutonga kwe ISO9001 uye TS 16949, Maitiro ese anoitwa kuburikidza nemazana epamberi kufa michina yekukanda, mishina-axis michina, uye zvimwe zvivakwa, zvinobva kumablasters kusvika ku Ultra Sonic yekuwachisa michina. timu yevainjiniya vane ruzivo, vashandisi uye vaongorori kuti zvigadzirwa zvemutengi zviitike.

Chibvumirano chinogadzira kufa kwekufa. Unyanzvi hunosanganisira inotonhorera kamuri aluminium kufa kukanda zvikamu kubva pa0.15 lbs. kusvika ku6 lbs., kukurumidza shanduko kumisikidzwa, uye machining. Kukosha-kwakawedzerwa masevhisi anosanganisira kukwiza, kudedera, kuita deburring, kupfura kupfura, kupenda, kupenda, kupfeka, kuungana, uye kushandisa. Zvishandiso zvakashanda pamwe zvinosanganisira alloys senge 360, 380, 383, uye 413.

Zinc kufa kukanda dhizaini rubatsiro / panguva imwe chete mabasa einjiniya. Tsika inogadzira chaiyo zinc kufa castings. Miniature castings, yakanyanya kumanikidza kufa castings, yakawanda-slide muforoma castings, yakajairwa muforoma castings, yuniti kufa uye yakazvimirira kufa castings uye mhango yakavharwa castings inogona kugadzirwa. Castings inogona kugadzirwa muhurefu uye hupamhi kusvika makumi maviri nemana mukati. Mu +/- 24 mukati. Shiviriro.

ISO 9001: 2015 yakasimbiswa inogadzira kufa cast magnesium, Kugona kunosanganisira yakakwira-yekumanikidza magnesium kufa kukanda kusvika 200 ton inopisa kamuri & 3000 toni kamuri inotonhorera, dhizaini dhizaini, kupora, kuumba, kugadzira, poda & pendi yemvura, yakazara QA ine CMM kugona , gungano, kurongedza & kuendesa.

ITAF16949 yakasimbiswa. Kuwedzera Kukanda Sevhisi Sanganisira utsvaga kukanda,jecha kukanda,Gravity Kukanda, Yakarasika Furo Kukanda,Kukanda kweCentrifugal,Vacuum Kukanda,Permanent Mould KukandaUnyanzvi hunosanganisira EDI, rubatsiro rweinjiniya, yakasimba modelling uye yechipiri kugadzirisa.

Kukanda Maindasitiri Zvikamu Nyaya Dzedzidzo dze: Mota, Mabhasikoro, Ndege, Zvimhanzi, Watercraft, Optical zvishandiso, Sensors, Models, Zvigadzirwa zvemagetsi, Mahombekombe, Mawachi, Michina, Injini, Furniture, Zvishongo, Jigs, Telecom, Mheni, Midziyo yekurapa, Mifananidzo yemifananidzo, Marobhoti, Zvivezwa, Zvishandiso zveruzha, Zvekushandisa zvemitambo, Matombo, Matoyi nezvimwe.

Chii chatinogona kukubatsira iwe kuti uite zvinotevera?

∇ Enda Kune Homepage Ye Die Kukanda China

→Kukanda Zvikamu-Tsvaga zvatakaita.

→ Ralated Matipi Nezve Vanofa Vanokanda Services

By Minghe Die Kukanda Mugadziri | Categories: Zvinyorwa Zvinobatsira |zvinhu Tags: Aluminium Casting, Zinc Kukanda, Magnesium Kukanda, Titanium Kukanda, Stainless Simbi Kukanda, Brass Kukanda,Bronze Kukanda,Kukanda Vhidhiyo,History History,Aluminium Die Casting | Comments Off