Maitiro ekuvandudza matanho ekukanda matanho eiyo spheroidization mwero

The spheroidization pamwero zvipfuwo zvavo spheroidal graphite cast iron castings inodiwa kusvika padanho rechina kana pamusoro, (kureva, iyo spheroidization mwero ndeye 4%), iyo spheroidization mwero unowanikwa neyakajairika foundry ingangoita 70%. Mumakore achangopfuura, pamwe nekuvandudzwa kwe nodular cast iron kugadzirwa, kunyanya mumaindasitiri ane akakwirira anodikanwa ekugadzira simba remhepo uye kurasa mhando, iyo spheroidization mwero inodiwa kusvika padanho repiri, ndiko kuti, iyo spheroidization mwero inosvika inopfuura 85%. Kambani yemunyori yakaongorora nekuvandudza iyo spheroidization uye inoculation maitiro anoshandiswa muQT2-90, pamwe neiyo spheroidizing mumiriri uye inoculant, kuti iyo spheroidization chiyero che nodular cast iron yakasvika kupfuura 400%.

1. Iyo yekutanga nzira yekugadzira

Chekutanga kugadzirwa maitiro:

- Iyo yekunyungudisa michina inotora 2.0T yepakati frequency tiravira uye 1.5T maindasitiri frequency frequency;

- Iko kuumbwa kweQT400-15 mbishi simbi mvura is ω (C) = 3.75% ~ 3.95%, ω (Si) = 1.4% ~ 1.7%, ω (Mn) ≤0.40%, ω (P) ≤0.07%, ω ( S)) -0.035%;

- Iyo spheroidizing mumiriri inoshandiswa mukurapa spheroidizing ndeye 1.3% kusvika 1.5% RE3Mg8SiFe chiwanikwa;

- Iyo inoculant inoshandiswa mukurapa inoculation i0.7% ~ 0.9% 75SiFe-C chiwanikwa. Iyo yekurapa spheroidizing inotora maviri ekugogodza uye ekutsvaira nzira:

Kutanga, 55% ~ 60% yesimbi inogadzirwa, uye spheroidizing inoitwa, ipapo inoculant inowedzerwa, uyezve iyo yakasara yesimbi yemvura inowedzerwa.

Nekuda kwemaitiro echinyakare e spheroidization uye inoculation, iyo spheroidization chiyero chakaonekwa neiyo imwechete cast wedge test block ine ukobvu hwe25 mm inowanzo kuve yakatenderedza 80%, ndokuti, iyo spheroidization nhanho ndeyechitatu.

2. Ronga bvunzo rekuvandudza mwero wespheroidization

Kuti uwedzere mwero wespheroidization, yekutanga spheroidization uye inoculation maitiro akagadziridzwa. Matanho makuru ndeaya: kuwedzera huwandu hwe spheroidizing mumiriri uye inoculant, kunatsa simbi yakanyungudutswa, uye kurapa kwekushayisa moyo. Iyo spheroidization mwero ichiri kuyedzwa neiyo imwechete cast wedge test block ye25 mm. Urongwa chaihwo hunotevera:

- (1) Ongorora chikonzero cheiyo yakaderera spheroidization mwero wepakutanga maitiro. Zvaifungidzirwa kuti huwandu hwe spheroidizing mumiriri hwaive hushoma, saka huwandu hwe spheroidizing mumiriri akawedzerwa yakawedzerwa kubva ku 1.3% kusvika ku 1.4% kusvika ku1.7%, asi iyo spheroidizing mwero haina kusangana nezvinodiwa. . (2) Imwe fungidziro ndeyekuti yakaderera spheroidization mwero inogona kukonzerwa nehurombo gestation kana kubereka kuderera. Naizvozvo, kuyedza kwakawedzera iyo inoculation dose kubva pa0.7% kusvika pa0.9% kusvika pa1.1%, uye iyo spheroidization mwero haina kusangana nezvinodiwa.

- (3) Ramba uchiongorora uye nekutenda kuti kune zvimwe zvinoiswa mukati mesimbi yakanyungudutswa uye yakakwirira spheroidization yekukanganisa zvinhu zvinogona kuve chikonzero cheiyo yakaderera spheroidization mwero. Naizvozvo, kupisa kwepamusoro-tembiricha kwesimbi yakanyungudika kunoitwa. Iyo yepamusoro-tembiricha yekunatsa tembiricha inowanzo kudzorwa pa1500 ± 10 ° C, asi Its spheroidization mwero haina kudarika 90%.

- (4) Iyo yakakwira huwandu hwe ω (S) zvakanyanya inoshandisa iyo spheroidizing dosi uye inomhanyisa kuderera kwespheroidization. Naizvozvo, kurapwa kwe desulfurization kunowedzerwa kudzikisira simbi yemvura original (S) kubva pa0.035% kusvika pasi pe0.020%, asi iyo spheroidization mwero zvakare Inongosvika 86%. Mhedzisiro yekuedzwa kwezvirongwa zvina zvataurwa pamusoro zvinoratidzwa muTafura 1. Maumbirwo uye michina zvivakwa zvemuchinjisa-wakaumbwa bvunzo bvunzo haina kusangana nezvinodiwa.

3. Chirongwa chekupedzisira chekuvandudza chakagamuchirwa

3.1 Matanho ekuvandudza

- Izvo zvakasvibirira inguruve yesimbi, isina ngura kana isina zvishoma ngura marara uye yekudzoreredza zvinhu;

- Desulfurization yesimbi yakanyungudutswa yesimbi nekuwedzera soda ash (Na2CO3) kuchoto;

- Shandisa Foseco 390 prereatment mumiririri pre-deoxidize muhomwe;

- Spheroidizing kurapwa neFozco Nodulizer;

- Uchishandisa silicon carbide uye ferrosilicon yakasanganiswa inoculation.

Iyo yekutanga simbi yakanyungudutswa yekugadzirisa kweichi chiitiko chitsva: ω (C) = (3.70% ~ 3.90%, ω (Si) = 0.80% ~ 1.20% [kukanda c (Si final) = 2.60% ~ 3.00%], ω ( Mn) ≤ 0.30%, ω (P) -0.05%, ω (S) -0.02% Kana simbi yakanyungudutswa yepakutanga S (S) inodarika 0.02%, indasitiri yesoda dota inoshandiswa pakudonhedza pamberi pevira, nekuti desulfurization reaction ndeye endothermic reaction, Iyo desulfurization tembiricha inodikanwa kuti igadziriswe panenge 1500 ° C, uye huwandu hwesoda madota yakawedzerwa inodzorwa pa 1.5% ~ 2.5% zvinoenderana nehuwandu hwe ω (S) panguva yekunyunguduka muvira .

Panguva imwecheteyo, iyo spheroidizing kurapwa pasuru inotora yakajairika dhamu mhando yekurapa package. Kutanga, wedzera 1.7% yeFoseco NODALLOY7RE brand spheroidizing mumiriri kudivi redamu pazasi pepakeji, flatten uye compact, uye shandisa 0.2% yeupfu hwesilicon carbide uye 0.3% diki Iyo hombe 75SiFe yakafukidzwa nehumwechete imwe mushure meimwe , uye mushure mekutsika, yakafukidzwa nesimbi yekumanikidza, uye 0.3% Foseke 390 inoculant inowedzerwa kune rimwe divi resimbi yakanyungudutswa. Paunenge uchirova simbi, 55% ~ 60% yehuwandu hwesimbi yakanyungudutswa inotanga kufuridzwa. Mushure mokunge spheroidizing reaction yapera, 1.2% 75SiFe-C inoculant inowedzerwa uye simbi yakasara yakanyungudutswa yasvinwa, uye iyo slag inodururwa.

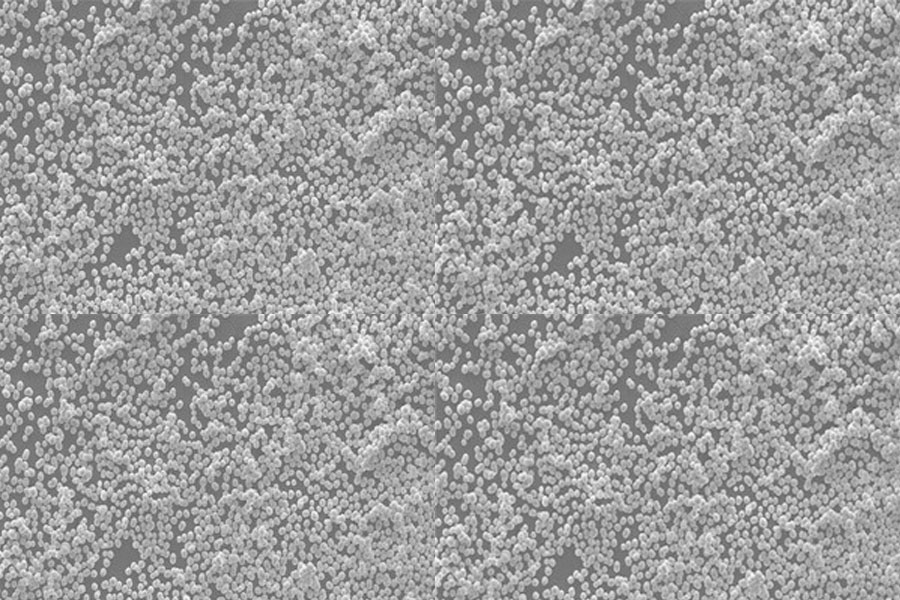

3.2 Mhedzisiro yebvunzo

Kuumbwa kwesimbi yakanyungudutswa yekutanga kusati kwapera uye mushure mekuparadzwa, iyo michina zvivakwa uye simbi yesimbigirafu yeiyo 25mm imwechete yakakanda wedhu-yakaita bvunzo bvunzo, uye nzira yekuongorora yeiyo spheroidization mwero mune yesimbilographic chimiro inoonekwa otomatiki neiyo metallographic mufananidzo ongororo system. .

4. Ongororo yemhedzisiro

4.1 Iko kukanganisa kweakakosha zvinhu pane iyo spheroidization mwero

- C, Si: C inogona kusimudzira graphitization uye kudzikisira maitiro emuromo chena, asi yakakwira huwandu hwe ω (C) ichaita kuti CE ive yakanyanya kukwirira uye nyore nyore kukonzera graphite kuyangarara, kazhinji inodzorwa pa3.7% ~ 3.9%. Si inogona kusimbisa kugona kwe graphitization uye kubvisa cementite. Kana Si ikawedzerwa seinoculant, inogona kudzikisa zvakanyanya kugona kwesimbi yakanyungudutswa.Ikuti ivandudzire inoculation mhedzisiro, huwandu hwe ω (Si) musimbi yakanyungudutswa yepakutanga yakaderedzwa kubva ku1.3% kusvika 1.5% kusvika 0.8% kusvika 1.2%, uye huwandu hwe ω (yekupedzisira Si) hwaidzorwa pa 2.60% kusvika 3.00%.

- Mn: Munguva yeiyo crystallization maitiro, Mn anowedzera maitiro esimbi yakakomberedzwa uye inosimudzira kuumbwa kwe carbides (FeMn) 3C. Mune eutectoid shanduko maitiro, Mn inoderedza iyo eutectoid shanduko tembiricha, inogadzikana uye inonatsa pearlite. Mn haina simba rakawanda pane iyo spheroidization mwero. Nekuda kwesimba rezvinhu zvakasvibirira, kazhinji zvinodzora ω (Mn) <0.30%.

- P: Kana ω (P) <0.05%, yakasimba-yakasungunuka muFe, uye zvinonetsa kuumba phosphorus eutectic, iyo ine simba shoma pane iyo spheroidization mwero weductile iron.

- S: S chinhu chinozvidzwa. S inodya Mg uye RE mune spheroidizing mumiririri panguva yekumhanyisa maitiro, ichitadzisa graphitization uye kudzikisa spheroidizing chiyero. Sulfide slag inodzoka zvakare kune sarufa simbi yakanyungudutswa isati yasimba, zvakare ichidya zvinhu zvinowedzera simba, zvichikurudzira kudzikira kwespheroidization, uye zvichizokanganisa mwero wespheroidizing. Kuti uwane yakakwira spheroidization chiyero, huwandu hwe ω (S) mune yakasvibira simbi inofanira kudzikiswa kusvika pasi pe0.02%.

4.2 Desulfurization kurapwa

Mushure mekunge mutero wanyungudutswa, tora sampuli uye woongorora makemikari akaumbwa. Kana huwandu hwe ω (S) hwakwira kupfuura 0.02%, desulfurization inodiwa.

Nheyo yesoda dota desulfurization ndeiyi: isa imwe huwandu hwesoda dota muduri, shandisa yakanyungudutswa simbi kuyerera kuyerera nekumhanyisa, soda madota inoora pakupisa kwakanyanya, maitiro fomura iri Na2CO3 = Na2O + CO2 ↑: iyo inogadzirwa Na2O iri mune simbi yakanyungudika zvakare Kuparadzwa uye kuumbwa kweNa2S, (Na2O) + [FeS] = (Na2S) + (FeO).

Na2CO3 inopatsanura uye inogadzirisa CO2, ichikonzera kusagadzikana kwechisimba kwesimbi yakanyungudutswa, iyo inosimudzira iyo desulfurization maitiro. Soda madota slag iri nyore kuyerera uye kuyangarara nekukurumidza, uye iyo desulfurization reaction nguva ipfupi. Mushure mekuparadzwa, iyo slag inofanira kubviswa munguva, zvikasadaro inodzokera kune sarufa. 4.3 Pre-deoxidation kurapwa, spheroidization kurapwa uye inoculation kurapwa Foseke 390 pretreatment mumiririri inoita basa re pre-deoxidation kurapwa muhombodo, uye panguva imwechete inowedzera graphite nucleation musimboti uye huwandu hwe graphite mabhora padanho reyuniti, uye inogona zvakare wedzera mwero wekutapa kweMg. Zvakanyanya kuvandudza kugona kurwisa hupfumi uye kuwedzera iyo spheroidization mwero. Fochke inoculant ine ω (Si) = 60% ~ 70%, ω (Ca) = 0.4% ~ 2.0%, ω (Ba) = 7% ~ 11%, iyo Ba inogona kutambanudza iyo inoshanda incubation nguva. Iyo NODALLOY7RE giredhi yeFozco Nodulizer inosarudzwa, uye yayo Si (Si) = 40% ~ 50%, ω (Mg) = 7.0% ~ 8.0%, ω (RE) = 0.3% ~ 1.0%, ω (Ca) = 1.5 % ~ 2.5%, ω (Al) <1.0%. Sezvo simbi yakanyungudika ichiita desulfurization uye pre-deoxidation kurapwa, izvo zvinhu zvinodya nodulizers musimbi yakanyungudutswa zvakaderedzwa zvakanyanya, saka nodulizer ine yakaderera huwandu hwe ω (RE) inosarudzwa kudzora kudzikira kweiyo spheroidal graphite morphology naRe. ; Chinhu chikuru chekuita ndiMg; Ca naAl vanogona kutamba chinzvimbo mukusimbisa incubation. Uchishandisa silicon carbide uye ferrosilicon yakasanganiswa inoculation kurapwa, iyo yakanyunguduka yesilicon carbide ingangoita 1600 ° C, uye graphite yekristaro nucleus inowedzerwa panguva yekusimbiswa, uye makuru madosi e ferrosilicon anoshandiswa kuita inoculation, iyo inogona kudzivirira spheroidization kubva kudzikira.

5 Mhedziso

Mukugadzirwa kwe ferritic nodular cast iron, kana iyo spheroidization chiyero ichidikanwa kuti isvike inopfuura 90%, anotevera matanho anogona kutorwa:

- (1) Sarudza yemhando yepamusoro kubhadharisa kudzikisira iyo de-spheroidization zvinhu zviri mubhadharo.

- (2) Sarudza spheroidizing mumiririri ane yakaderera huwandu we ω (RE) kudzikisira kudzikira kweRe pa morphology ye spheroidal graphite.

- (3) Iyo ω (S) yemukati yesimbi yakanyungudutswa yepakutanga inofanira kunge iri pasi pe0.020%, iyo inogona kudzikisira kudyiwa kwemadimulizers, kunyanya zvinhu zvine musoro zvinodyiwa neiyo yechipiri sulfurization yesulpide slag.

- (4) Pre-deoxidize iyo yakanyungudutswa simbi, kuwedzera huwandu hwe graphite mabhora padanho reyuniti, kuwedzera spheroidization mwero, kunatsiridza zvakanyanya kugona kurwisa hupfumi, uye kuwedzera inoshanda incubation nguva.

- (5) Deredza huwandu hwe ω (Si) mune yesimbi yakanyungudutswa yepakutanga, wedzera huwandu hwe spheroidizing mumiriri, inoculant uye akasiyana prereatment vamiririri, uye simbisa iyo inoculation kurapwa.

Ndokumbirawo uchengete kwainobva nekero yechinyorwa chino kuti iprote zvakare: Maitiro ekuvandudza matanho ekukanda matanho eiyo spheroidization mwero

Minghe Kambani Inokanda Kambani dzakatsaurirwa kugadzira uye kupa mhando uye epamusoro kuita Kukanda Zvikamu (simbi kufa zvikamu zvekukanda mhando zvinonyanya kusanganisira Mutete-Wall Yakakanda Kukanda,Hot Chamber Die Kukanda,Cold Chamber Die Kukanda), Round Sevhisi (Die Kukanda Service,Cnc machine,Kugadzira Mould, Surface Kurapa) .Chero tsika yeAluminium kufa kukanda, magnesium kana Zamak / zinc kufa kukanda uye zvimwe zvinodiwa zvekukanda zvinogamuchirwa kuti utibate.

Pasi pekutonga kwe ISO9001 uye TS 16949, Maitiro ese anoitwa kuburikidza nemazana epamberi kufa michina yekukanda, mishina-axis michina, uye zvimwe zvivakwa, zvinobva kumablasters kusvika ku Ultra Sonic yekuwachisa michina. timu yevainjiniya vane ruzivo, vashandisi uye vaongorori kuti zvigadzirwa zvemutengi zviitike.

Chibvumirano chinogadzira kufa kwekufa. Unyanzvi hunosanganisira inotonhorera kamuri aluminium kufa kukanda zvikamu kubva pa0.15 lbs. kusvika ku6 lbs., kukurumidza shanduko kumisikidzwa, uye machining. Kukosha-kwakawedzerwa masevhisi anosanganisira kukwiza, kudedera, kuita deburring, kupfura kupfura, kupenda, kupenda, kupfeka, kuungana, uye kushandisa. Zvishandiso zvakashanda pamwe zvinosanganisira alloys senge 360, 380, 383, uye 413.

Zinc kufa kukanda dhizaini rubatsiro / panguva imwe chete mabasa einjiniya. Tsika inogadzira chaiyo zinc kufa castings. Miniature castings, yakanyanya kumanikidza kufa castings, yakawanda-slide muforoma castings, yakajairwa muforoma castings, yuniti kufa uye yakazvimirira kufa castings uye mhango yakavharwa castings inogona kugadzirwa. Castings inogona kugadzirwa muhurefu uye hupamhi kusvika makumi maviri nemana mukati. Mu +/- 24 mukati. Shiviriro.

ISO 9001: 2015 yakasimbiswa inogadzira kufa cast magnesium, Kugona kunosanganisira yakakwira-yekumanikidza magnesium kufa kukanda kusvika 200 ton inopisa kamuri & 3000 toni kamuri inotonhorera, dhizaini dhizaini, kupora, kuumba, kugadzira, poda & pendi yemvura, yakazara QA ine CMM kugona , gungano, kurongedza & kuendesa.

ITAF16949 yakasimbiswa. Kuwedzera Kukanda Sevhisi Sanganisira utsvaga kukanda,jecha kukanda,Gravity Kukanda, Yakarasika Furo Kukanda,Kukanda kweCentrifugal,Vacuum Kukanda,Permanent Mould KukandaUnyanzvi hunosanganisira EDI, rubatsiro rweinjiniya, yakasimba modelling uye yechipiri kugadzirisa.

Kukanda Maindasitiri Zvikamu Nyaya Dzedzidzo dze: Mota, Mabhasikoro, Ndege, Zvimhanzi, Watercraft, Optical zvishandiso, Sensors, Models, Zvigadzirwa zvemagetsi, Mahombekombe, Mawachi, Michina, Injini, Furniture, Zvishongo, Jigs, Telecom, Mheni, Midziyo yekurapa, Mifananidzo yemifananidzo, Marobhoti, Zvivezwa, Zvishandiso zveruzha, Zvekushandisa zvemitambo, Matombo, Matoyi nezvimwe.

Chii chatinogona kukubatsira iwe kuti uite zvinotevera?

∇ Enda Kune Homepage Ye Die Kukanda China

→Kukanda Zvikamu-Tsvaga zvatakaita.

→ Ralated Matipi Nezve Vanofa Vanokanda Services

By Minghe Die Kukanda Mugadziri | Categories: Zvinyorwa Zvinobatsira |zvinhu Tags: Aluminium Casting, Zinc Kukanda, Magnesium Kukanda, Titanium Kukanda, Stainless Simbi Kukanda, Brass Kukanda,Bronze Kukanda,Kukanda Vhidhiyo,History History,Aluminium Die Casting | Comments Off